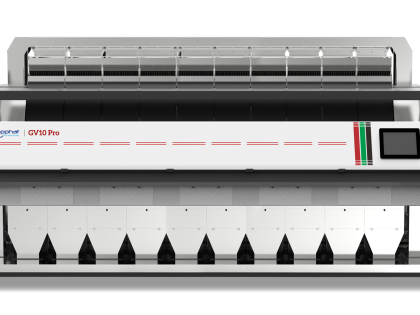

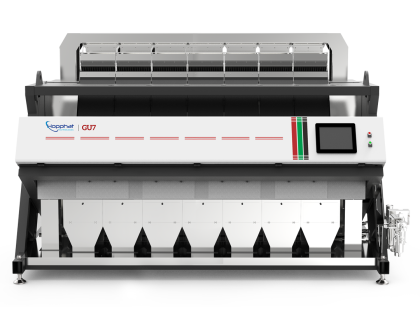

GI5 PRO – PLASTIC GRANULE COLOR SORTING MACHINE

-

I pro series is mainly used for the separation and purification of PET/PP/PE/PC/atloy/PMMA/ABS/PS/PVC/nylon/POM and other materials.

- It can be used for the sorting and purification of high-quality AAA flakes, blue-white flakes, engineering materials and tailings, creating greater utilization value.

- Excellent sorting performance in the identification and separation of PET and non-PET, with ultra-low carry-out, powder handling, reverse sorting capabilities, and lower losses.

- Using a single I pro machine can achieve a variety of material sorting, unique inversion function, and processing of tailings.

- It can identify and remove special materials such as aluminum sheets, springs, and wood. Special cameras can be customized for a certain key material to improve the output and recovery rate of key materials and reduce losses.

-

A variety of special cameras are continuously updated, such as PVC/(PP, PE), ABS/PS and other special cameras.

- Description

Description

OVERVIEW

GI5 Pro plastic color separator helps identify and classify non-PET/ PP/ PE plastic materials in PET/ PP/ PE materials such as PET/ PP/ PE/ PC/ Alloy/ PMMA/ ABS/ PS/ PVC/ NYLON/ POM and other materials depending on customer requirements.

PRODUCT FEATURES

All-in-one Separator

Combining NIR technology, S-class high-precision multi-spectral infrared camera with maintenance free light source cooling scheme and long-life infrared light source, using an I pro machine can realize the sorting function for various materials. Special cameras can be customized for your certain material.

High and Stable Throughput

Large output vibrator, multi-channel sorting, anti-blocking material design, support long-term unmanned control work, fully meet your production needs

Affordable and Reduce Your Energy Consumption

It can also be selected at one time as multiple selection and 5 selections, which has strong applicability and can be adjusted according to the actual process.

High Accuracy

High-speed sensors, chips and “missile guidance” systems ensure the sorting accuracy rates as high as 99%.